Polishing aluminum

Restoring and Protecting Dull Aluminium

Polishing aluminium is the best way to restore dull aluminium and protect it from further damage. At Van Geenen, we specialise in grinding and polishing aluminium, resulting in a high-quality finish, both aesthetically and technically. Whether for functional applications in machine building or shiny façade panels, our polishing process ensures a perfect look for your aluminium products.

What is polishing aluminium?

Polishing aluminium is a process where the surface of aluminium is smoothed and buffed to achieve a shiny, reflective finish. During this process, imperfections such as scratches and machining marks are removed by sanding and polishing with increasingly finer abrasives.

The end result is a smooth, glossy surface that is not only aesthetically pleasing but also more resistant to corrosion and contamination. Polishing aluminium is often used in industries where both the appearance and functionality of the material are important, such as aerospace, architecture, and manufacturing.

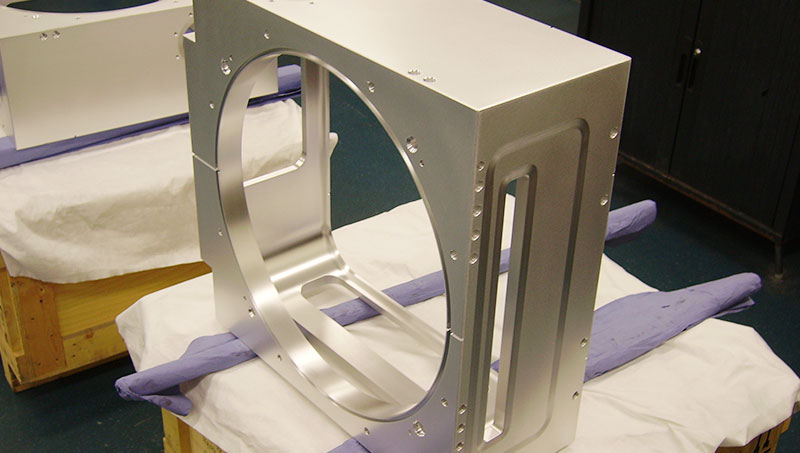

Fig. 1 A process chamber for the semiconductor industry, which was milled from a solid block by our customer. Van Geenen has removed these processing traces and the surfaces are provided with a beautiful, even, directionless brush finish. In addition, O-rings have been fitted that serve as a sealing surface. The products are ready to be cleaned and packaged under cleanroom conditions.

Why polish aluminium?

Aluminium that comes directly from the factory is often rough and shows signs of machining, such as turning and milling marks. By grinding and polishing aluminium, you can restore dull surfaces, prevent corrosion and further damage, and achieve a high level of gloss that is both aesthetically and functionally superior. This process is especially important when aluminium remains visible in a construction or when it is exposed to harsh conditions, such as in the aerospace industry or façade construction.

Fig. 2 These aluminum panels have been polished by Van Geenen. They are then clear anodized and this beautiful, soft shine with a slightly reflective effect is created.

Applications of Polished Aluminium

1. Machine and Equipment Building

In machine building, aluminium is widely used due to its lightweight and excellent machinability. After processes like turning and milling, machining marks often remain on the material, which must be removed to achieve a smooth final finish. Depending on the requirements, the surface can be ground, polished, or brushed, with a combination of techniques often providing the best results.

Polishing aluminium for technical applications is not only for aesthetics but also ensures a smooth surface that is less susceptible to dirt and damage. This is particularly important in high-tech sectors.

2. Façade Construction

In façade construction, aluminium is often used for its lightweight and durability. The material is often anodized to create a wear-resistant and corrosion-proof layer. Polishing in combination with anodizing adds an extra dimension to the material, giving it a brilliant glossy or even mirror-like effect. This makes it ideal for modern, sleek façades that need to make an impression.

Many architects choose polished and anodized aluminium cassettes for façades because of their low maintenance and aesthetic properties. These cassettes remain looking new for years and provide long-lasting protection against the elements.

Fig. 3 In this photo you see a milled aluminum part, which has been finely ground + polished by Van Geenen.

The process of polishing aluminium

Polishing aluminium is a craft that must be carried out carefully to achieve the best results. During the process, the aluminium is prepared step by step through grinding. It is important to use the right grit size and ensure that the material does not overheat. This prevents deformation and ensures that the aluminium is ready for the final polishing step.

Once properly prepared, the aluminium can be polished to a mirror finish. This is especially desired in aesthetic applications where a high gloss or even a super high gloss is required, such as in the Mirror 8 technique. This technique delivers a scratch-free, reflective finish that is almost unmatched in clarity.

Manual and mechanical polishing

At Van Geenen, we combine both manual and mechanical techniques to guarantee the best results. Manual polishing allows for attention to specific details, such as hard-to-reach corners or small surfaces. Mechanical polishing, on the other hand, provides speed and consistency, especially on larger surfaces.

The combination of manual and mechanical polishing ensures a perfect balance between precision and efficiency. This allows Van Geenen to always deliver a high-quality finish, regardless of the complexity of the product.

Shiny Aluminium: Different Finishes

At Van Geenen, we offer various finishes depending on the application and the desired end result. One of the most popular finishes is high-gloss polishing, which gives the aluminium a mirror-like effect. This is not only visually appealing but also offers practical advantages, such as a smooth surface that attracts less dirt.

For those who want to go further, there is the Mirror 8 technique, which provides an ultra-high-gloss finish with an extreme mirror effect. This is often used in applications where aesthetics are of the highest importance, such as in exclusive architectural projects and design products.

Frequently asked questions about aluminium surface treatment

1. How long does polished aluminium stay shiny?

The durability of polished aluminium’s shine depends on various factors, such as the environment in which the aluminium is used and the maintenance it receives. In an indoor environment where the aluminium is not exposed to harsh weather conditions or chemicals, the shine can last for years with minimal maintenance. In an outdoor environment, such as façade panels, polished aluminium can become dull due to exposure to rain, dirt, and air pollution. Regular cleaning and maintenance with appropriate products can significantly extend the lifespan of the shine.

2. What are the costs of polishing aluminium?

The cost of polishing aluminium varies depending on several factors, such as the size of the surface, the degree of polishing (high gloss, mirror finish, etc.), and the complexity of the product. Smaller surfaces or simple objects will generally be less expensive than larger or complex constructions. For an accurate quote, we recommend contacting us so we can provide a customised offer based on your specific project and requirements.

3. What is the difference between polishing and anodizing aluminium?

Polishing and anodizing are two different processes for treating aluminium. Polishing removes imperfections and gives aluminium a smooth, glossy, or mirror-like finish, which offers mainly aesthetic benefits and makes the surface more resistant to dirt and corrosion. Anodizing, on the other hand, is an electrochemical process that applies a hard, protective oxide layer to the aluminium. This layer protects the material better against corrosion and wear. Polished aluminium is often anodized to offer both a beautiful finish and extra protection, especially in façade construction or other harsh environments.

Polishing Aluminium at Van Geenen

Van Geenen has many years of experience in polishing aluminium. Our team of professionals has the knowledge and skills to complete both simple and complex polishing jobs to perfection. Thanks to our modern machinery and artisanal craftsmanship, we can offer a wide range of surface finishes, always with attention to detail and quality.

With us, you not only get the best finish but also customised advice. Whether it’s small series or large projects, Van Geenen always delivers high-quality service and results that meet your expectations.

Contact Van Geenen

Are you looking for a reliable partner for polishing aluminium? Van Geenen is the specialist in the Netherlands in this field. Contact us today for a quote or to discuss your project. We are happy to assist you in polishing aluminium for your specific application.