Pipes, Tubes and Strips

Grinding and polishing

Internal grinding round pipe

Piping in the food and pharmaceutical industries must remain free of adhesion at all times in order to prevent bacterial growth and more. The product that goes through the pipes should flow through effortlessly, which is why smooth internal surfaces are required. Up to 2 mm wall thickness, you can often choose dairy tube in 304/316 stainless steel, which is already manufactured very smoothly. In the case of deviating, more special types of material and thicker walls, the internal Ra values are often rougher and should be reduced by grinding.

Van Geenen has 3 machines for internal pipe grinding, in the following diameter range.

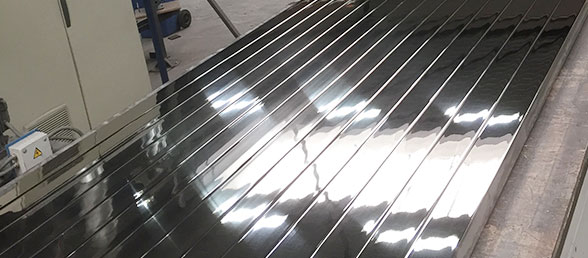

External grinding and polishing round pipe

In addition to the very common K240 / K320 grinding, Van Geenen has very good options for high-gloss tube polishing. In various gradations, from shiny to Super Mirror 8/9.

Depending on how the pipes are processed further, it can be determined how intensively the pipes are pre-treated.

Cleanroom

High-level cleaning and packaging

Your product leaves our facility clean and securely packaged in protective foil. We use cleaning baths, ultrasonic baths, and clean packaging rooms. For advanced projects, we offer cleanroom facilities and certifications to meet the highest industry standards.

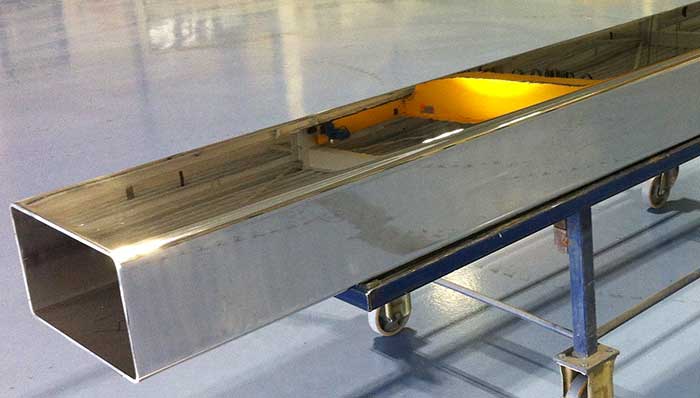

Grinding and Polishing of Tubes, Box Sections, and Strips

A Durable and Sleek Finish for Stainless Steel

Stainless steel (Inox or AISI) is one of the most widely used refined metals in the metalworking industry. Every day, kilometers of stainless steel tubes, box sections, and strips are ground and polished to achieve a high-quality finish. This material is not only extremely strong but can also be adapted to specific applications without requiring an additional (galvanic) coating.

Why grind and polish tubes, box sections, and strips?

Grinding or polishing stainless steel tubes, box sections, or strips is often done with a specific purpose in mind. With grinding and polishing, we can:

- Reduce surface roughness for a smoother finish.

- Seal pores to enhance corrosion resistance.

- Achieve a high-gloss or mirror finish for an aesthetic upgrade.

Curious about the possibilities? Contact Van Geenen for expert advice and a customized solution.

A solution to any finish

Our range of Machines