Precision Grinding

Magnetic and non-magnetic materials

Precision grinding Titanium

Titanium is an exceptionally lightweight material, weighing approximately half as much as stainless steel. At the same time, it is extremely strong and highly resistant to corrosion. These unique properties make titanium a preferred material in industries such as aerospace.

To make titanium suitable for use, precise machining is essential. At Van Geenen, we offer advanced facilities to grind titanium plates with precision and within specified tolerances.

Precision grinding Stainless Steel

In various industries, such as mechanical engineering, standard thicknesses often fail to meet requirements. For many applications, precise and exact thickness dimensions are essential.

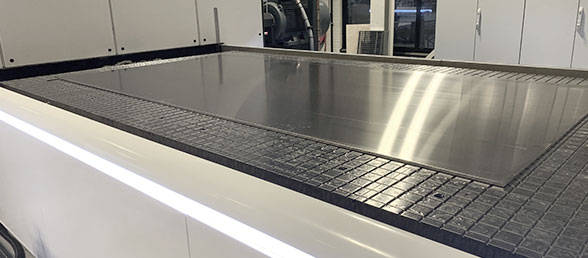

At Van Geenen, we provide the capability to grind stainless steel (inox) with precision, ensuring compliance with the desired thickness tolerances. Using our vacuum table, plates can be quickly and securely mounted without clamps, enabling efficient material removal.

Precision grinding Aluminium

Precision grinding of aluminium requires a meticulous process to prevent quality loss and unwanted effects. Aluminium cannot be ground “dry” as this leads to overheating and molecular changes. Especially on larger surfaces, this can result in stains or colour variations.

With the wet grinding process of our advanced Timesavers 8000 series, these issues are completely eliminated. At Van Geenen, we provide the perfect solution for both technical and visual challenges, ensuring a consistent and high-quality finish.

From a technical perspective, it is advisable to grind aluminium sheets to the desired thickness before performing further machining operations. Our advanced grinding process allows large aluminium plates to be easily and accurately clamped, offering greater precision than traditional machining techniques. As a result, only specific details, such as slots, need to be milled afterwards, significantly improving both efficiency and accuracy of the final product.

Precision grinding various Materials

At Van Geenen, we utilize advanced grinding techniques to accurately process a wide range of materials. By using different grinding belts, our machines achieve optimal grip on each material type, ensuring an efficient and consistent finish.

A prime example is the grinding of plastic press plates, where maintaining a uniform thickness across the entire surface is crucial. Additionally, harder materials such as Invar, Duplex, and special alloys can be processed with high precision. Our advanced grinding processes ensure that even the most demanding materials are finished within strict tolerances.

With our expertise and state-of-the-art technology, we guarantee a high-quality finish, optimal flatness, and precise dimensions tailored to your specific application requirements.

Cleanroom

High-level cleaning and packaging

Your product leaves our facility clean and securely packaged in protective foil. We use cleaning baths, ultrasonic baths, and clean packaging rooms. For advanced projects, we offer cleanroom facilities and certifications to meet the highest industry standards.

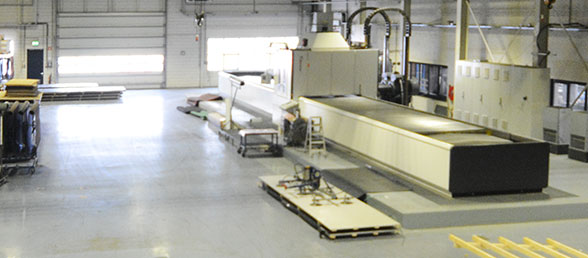

Precision Griding of Large Sheet Metal

Superior Flatness and Accurate Tolerances

In industries such as tank and equipment construction, aerospace, and high-tech manufacturing, the demand for ultra-precise ground sheet metal is greater than ever. Van Geenen offers an advanced precision grinding solution as a perfect alternative to conventional machining. Thanks to our large vacuum table, we can grind sheet metal in almost any size, without limitations. Additionally, both magnetic and non-magnetic materials can be securely and efficiently clamped.

Why Choose Precision Grinding at Van Geenen?

✔ Extremely accurate thickness tolerances – Grinding to 0.05 mm precision

✔ Superior flatness and surface roughness values – Perfectly smooth and consistent surfaces

✔ Ideal for challenging materials – Titanium, stainless steel, aluminum, and more

✔ Perfect for industries where precision is crucial – Aerospace, high-tech, and machinery construction

✔ Large vacuum table – Almost unlimited dimensions

Precision Grinding for Titanium and Other Difficult Materials

Certain materials, such as titanium, are naturally difficult to machine. Due to its high flammability, titanium cannot be processed on dry grinding machines. Van Geenen provides the solution with an innovative wet grinding process, enabling titanium and other difficult-to-grind metals to be safely and precisely finished. This is essential for industries such as aerospace, where every gram counts and tight tolerances are required.

Advanced Grinding Technology for Maximum Precision

At Van Geenen, we use a stock-removing grinding technique with an abrasive belt. Unlike standard grinding machines, where the grinding head follows the sheet’s irregularities, our grinding head remains fixed. This ensures that the sheet is perfectly leveled, achieving an exceptionally consistent thickness with a precision of just 0.05 mm.

Precision Grinding: The Key to Perfectly Customized Sheet Metal

Our advanced technology allows standard-rolled sheet metal to be ground to the exact required thickness, meeting the strictest specifications. The result? High-quality, ultra-precise ground sheet metal that meets the highest industry standards

Do you want perfectly ground sheet metal with minimal tolerances? Contact Van Geenen today and discover the advantages of our precision grinding process!

A solution to any finish

Our range of Machines