What is 316 Stainless Steel

everything you need to know

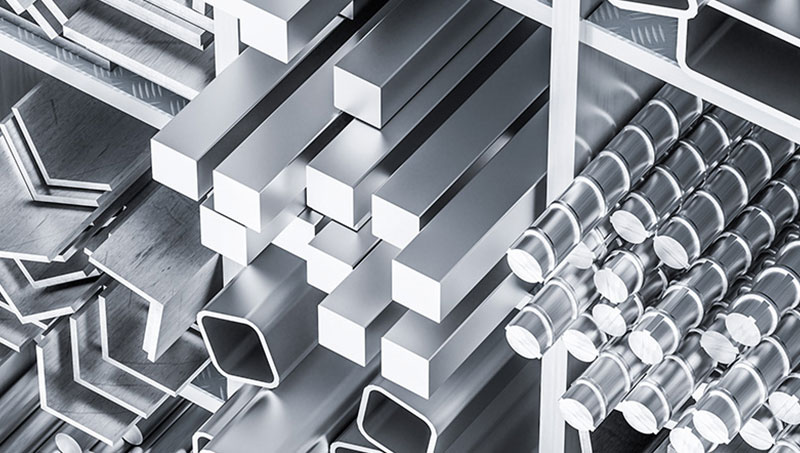

Stainless steel is a material used in numerous applications due to its durability and corrosion resistance. Type 316 Stainless Steel, also known as 316 Stainless, AISI 316 or A4 Stainless Steel, is a variant of stainless steel that is particularly popular for its unique properties and versatility.

A4 Stainless Steel is a stainless steel alloy with a high content of chromium and nickel. The exact composition of 316 Stainless Steel is 16% chromium, 10% nickel, and 2% molybdenum. This specific composition gives AISI 316 its superior properties, including high corrosion resistance, even in aggressive environments such as seawater and chemical installations. The molybdenum in the alloy enhances its resistance to acids and chlorides, making A4 Stainless Steel suitable for a wide range of applications.

Fig. 1 What is 316 Stainless Steel? We’ll explain it to you.

Properties of A4 Stainless Steel

The properties of 316 Stainless make it an excellent choice for various industries and applications:

- Corrosion Resistance: AISI 316 is highly resistant to corrosion, making it ideal for use in maritime environments and chemical installations.

- Heat Resistance: This alloy retains its strength and corrosion resistance at high temperatures, making it suitable for applications such as heat exchangers.

- Strength: Type 316 Stainless Steel has good tensile strength and is resistant to wear and deformation.

- Non-Magnetic: It is a non-magnetic material, which can be advantageous in certain applications.

- Hygienic: 316 Stainless Steel complies with strict hygiene standards and is often used in the food and pharmaceutical industries.

A4 vs A2 Stainless Steel

A common question when choosing stainless steel is the choice between 316 Stainless and 304 Stainless. Both alloys have their own advantages and applications. AISI 316 is generally more expensive than 304 Stainless (AISI 304) due to the additional alloying elements such as molybdenum. If corrosion resistance is crucial for your application, type 316 Stainless Steel is the better choice. However, 304 Stainless Steel may be more suitable for applications where cost is a significant factor and where less corrosion resistance is required.

Pros and Cons of 316 Stainless Steel

Pros

- Excellent Corrosion Resistance: 316 Stainless is resistant to corrosion in aggressive environments, making it suitable for maritime and chemical applications.

- Heat Resistance: It retains its strength at high temperatures, making it ideal for applications with heat exposure.

- Longevity: Thanks to its resistance to corrosion and wear, 316 Stainless Steel has a long service life, resulting in lower replacement costs.

- Hygienic: It complies with strict hygiene standards and is safe for use in the food and pharmaceutical industries.

Cons

- Cost: Type 316 Stainless Steel is generally more expensive than some other stainless steel alloys, such as type 304 Stainless Steel.

- Machinability: Machining, grinding, and polishing of 316 Stainless require specialized techniques and tools due to the hardness of the material.

- Not suitable for all applications: While versatile, A4 Stainless steel is not always the best choice for applications where low cost and moderate corrosion resistance are sufficient.

Price of 316 Stainless Steel

The price of Inox 316 can vary depending on market conditions, the supplier, and the quantity you require. Generally, type 316 Stainless Steel is more expensive than A2 Stainless Steel due to the additional alloying elements. For the most up-to-date price information, you can contact a reliable supplier.

Frequently Asked Questions (FAQs) about 316 Stainless

Grinding and Polishing of 316 Stainless

Type 316 Stainless Steel can be machined, ground, and polished to achieve the desired surface finish. However, grinding and polishing of AISI 316 require specific techniques and tools due to the hardness and toughness of the material. Van Geenen is the expert in grinding, polishing, and cleaning 316 Stainless Steel. Want to know more? Contact one of our specialists; they will be happy to assist you.