Aluminium sheet

Aluminum is a very popular type of material and is used for the most diverse products.

In the aircraft industry but also in home appliances, antennas, buildings and construction. Firstly, very light, because steel is 3 times as heavy. But just as durable and strong and also affordable.

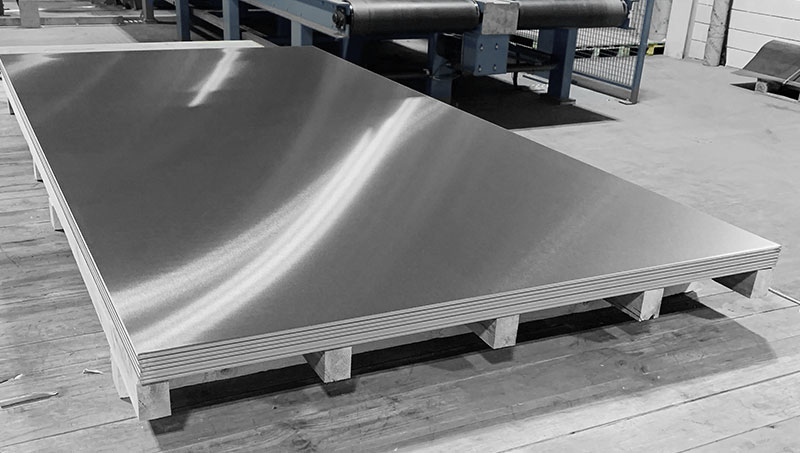

Fig. 1 Aluminum sheet polished brushed.

Aluminum plates

Available in rolled and cast condition. Cast plates are often in the thicker range and are widely used in the machining industry. Because it can be worked well on the milling and grinding machine because it is quite homogeneous in structure and low in tension. Cast plates often receive a special heat treatment to eliminate as much stress in the material as possible. This gives the cast aluminum plates great shape stability. This is of course nice if the aluminum sheet has to be machined within very precise tolerances, such as thickness and flatness tolerances. Aluminum cast plates are technically easy to anodize, so that a kind of protective layer is created. Decorative anodizing is highly dependent on the alloy chosen.

Custom aluminum plate

An aluminum sheet is of course easy to obtain in the trade, but is of course not tailor-made for the end application. The aluminum sheet can be sawn or cut to the desired size. Or be ground to thickness at Van Geenen, within very accurate thickness and flatness tolerances (+- 0.05). The plate can continue to its final destination, or it can be further processed on the milling machine. Make slots, holes or other recesses. Aluminum is very sensitive without surface treatment and therefore a coating is recommended.

Anodizing Aluminum

Anodising is a frequently chosen coating. By anodizing aluminum the corrosion resistance is increased and a very hard layer is created, which is also wear-resistant. That is why it is also a popular material in construction, it is light and very durable due to the anodization layer. This anodization can be carried out in various colours, and as a result it also acquires a visual, decorative function. Van Geenen supports this by grinding, brushing or polishing the aluminum plates before anodizing. Because the anodized layer is very thin, it comes through and gives impressive effects. Van Geenen provides this on stainless steel by means of a PVD coating. Many combinations are possible with both methods, ask for the possibilities for your application.

This also makes cleaning aluminum sheet much easier. The aluminum plate has been given a dense, smooth layer, and the dirt does not penetrate the material but lies on it, as it were.

This draws a parallel with the AFP / ETC concept (Anti-Finger-Print / Easy-to-Clean that Van Geenen offers on stainless steel plate, by means of nanopaints. This layer also provides an easily cleanable surface with anodized aluminum and can therefore last for years.

Aluminum weight

Aluminum sheet is widely used in various industries because of its weight. How do you calculate the weight of, for example, a 2mm aluminum plate? It is good to first elucidate the concept of “specific gravity” in more detail. This refers to the number of kilograms per cubic meter, and is therefore different for each type of material. It has to do with the density of the material. If you know the specific gravity of a type of material, the weight of a plate is fairly easy to determine with a formula. The specific gravity of Aluminum is 2,755 kg/m³.

This formula is: length in meters x width in meters x thickness in mm x specific weight.

So take this calculation example: What is the weight of this plate.

– Customized aluminum plate 2mm thick

2300 x 1350 x 2mm.

Formula : 2.3 x 1.350 x 2 x 2.755 = 17.10855 Kilogram

You can of course easily change the thickness to 1 or 3 mm, and calculate this.

If you know the similar weight of other materials, you can also use this simple formula. (for example Concrete 2,400 kg/m³ Steel 7,850 kg/m³ and stainless steel 7,930 kg/m³)

Application Customized aluminum sheet

Fig. 2 Custom aluminum sheet.

The part in this photo has gone through the necessary process steps. It arrived at Van Geenen as a rectangular, thick aluminum plate of 30mm for grinding to thickness, 27.5mm with a thickness tolerance of +- 0.05mm. The customer then milled the contours and holes in it. The plate returned to Van Geenen, where the surfaces of the aluminum plate were brushed in a directionless finish ( Angel Hair, Vibrationfinish ), and a sealing surface / “O-ring” was also applied with a roughness of RA < 0.4.

Contact us

Do you need a custom aluminum sheet? Please contact us directly. We stand for a perfect finish, high quality and an end result that meets all your wishes. You can reach us on telephone number +31 (0)548 – 543793, or send an e-mail to info@vangeenen.nl.