Machine grinding and polishing

Van Geenen has a very extensive machine park

Van Geenen is the proud owner of an extensive a range of modern machinery especially for the purposes of grinding as well as high-gloss polishing up to Mirror 8 grade. There are no limitations to our grinding and polishing capabilities. From small-size sheets and sheets/plates all the way up to a wide range of parts, we can produce any type of surface finish you want.

With our modern machine park, we can provide a solution for any particular surface finish you may desire. In addition, our machines do not require an operator, which means that two grinding machines can be worked at the same time with a single supervisor, so we can turn your order around quickly at an attractive price.

Our modern machine park comprises the following machines::

- Long-belt grinding machines sheet dimensions of up to 16,000 x 6,000 mm, unlimited thickness

- Wide-belt grinding machines sheet dimensions of up to 14,000 x 2,000 mm, unlimited thickness

- Polishing machines sheet dimensions up to 16,000 x 3,500 mm, unlimited thickness

- 5-head grinding machines Use for grinding tubes, strips and flat staves

- In addition, Van Geenen owns a variety of wide-belt machines that can produce an extensive range of cutting parts with unlimited thickness.

Please get in touch to find out what the possibilities are.

Fig. 1 Extensive machinepark at Van Geenen.

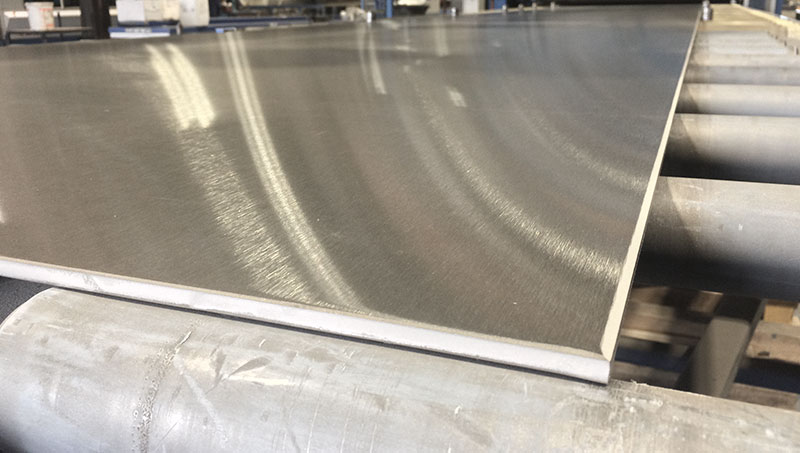

Grinding

At Van Geenen’s, you will find a number of long-belt grinding machines capable of grinding sheets/plates in sizes up to 16,000 x 6,000 mm. The size of the sheets/plates is immaterial; however, the thicker the sheet, the more difficult it is to achieve the right finish. Van Geenen has a wealth of experience, especially when it comes to grinding and polishing thicker sheets/plates, the so-called hot-rolled or Quattro sheets/plates. If you want your product to have a certain visual aspect or be graded to a particular Ra value… Van Geenen is the answer to all your needs.

We can achieve any finish you desire: grinding to a particular grit size, high-gloss polishing or meeting a particular Ra value. ( Ra-value) Hot-rolled sheets – often abbreviated to 1D – are characterised by their thick and tough skin that contains irregularities, small dents and other damage.

To achieve the desired finish, it is of the highest importance to grind the surface in the right order. With our highly advances machines in combination with our know-how, we always manage to achieve the desired surface finish. Our machines have the additional advantage that the sheets/plates can also be ground widthways irrespective of the dimensions and the size of the plate.

Fig. 2 Machine grinding Van Geenen.

Tubes, strips and cutting parts

Our range of advanced grinding machines enables us to grind strips, tubes and cutting parts to the highest standard. As before, we can achieve any finish you desire. We can grind to a specified grit size as well as to an Ra value.

High-gloss polishing

Van Geenen is also your supplier of choice for machine polishing of metal sheets. Whether they are made of stainless steel, aluminium, copper or brass, our quality workforce will machine-polish them to the highest standards. Thanks to our professional team and extensive machine park, we are unrivalled when it comes to polishing metal sheets to a perfect high gloss.

High-gloss polished sheets – also called Mirror sheet – can be polished to a range of qualities. We are able to polish up to Mirror 8 grade, which equals a high-quality, entirely perfect high-gloss mirror sheet which is used in superyacht building and the semiconductor industry, for example.

Fig. 3 Example of machine-polished high-gloss columns.

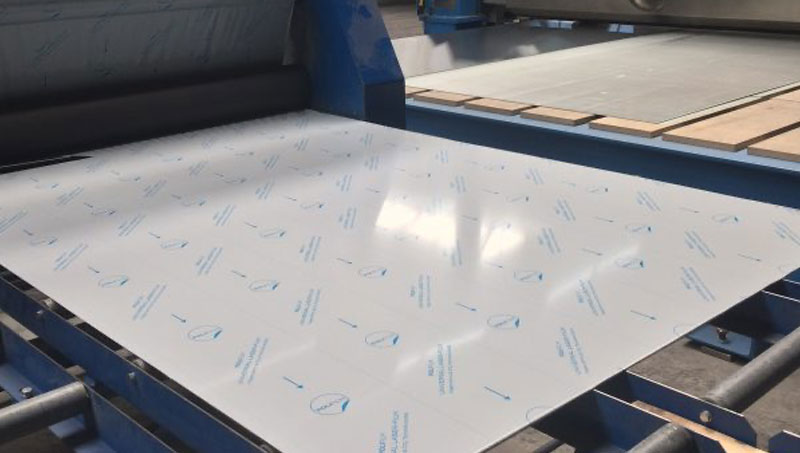

Foils

As standard, all of our sheets/plates, strips, tubes and other products have an application of foil during processing to protect the material. Do you only want your material to be laminated? Once again, Van Geenen provides the solution. We have a suitable foil for any type of material and product to ensure that your products are protected during processing and arrive at their destination safely.

Our foil is highly suitable for cutting after grinding and polishing. Our laminating machine can apply foil to one or both sides of the product with a maximum size of 14,000 x 2,000 mm. Please contact us if you require different sizes.

Fig. 4 We also provide foil for plates to protect the end product.