to life

since ‘77

Grinding & Polishing

Since ’77

Our experience enables us to give expert advice on grinding and polishing in order to help you achieve the best possible result. The constant pursuit of optimal quality and reliability with fair pricing is the basis of our company.

The latest news

ISO – 9001 certified since 1995. Click here for our certifications

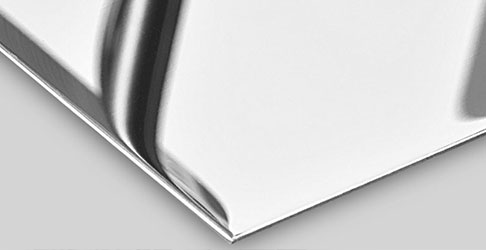

A selection of our finishes

A selection of our finishes

If you are going to make sheet metal products that ultimately need a high-quality finish or have to meet roughness requirements, it is important to use ground or polished sheets. This already provides a good basis for your product and there is minimal need for finishing after production. The same applies to your pipes, profiles and cutting parts.

Do you have to deal with highly accurate dimensions for flat and parallel products, or products with accurate thickness requirements? We can accurately grind your sheet metal to size with our precision grinding machines. Also exotic materials such as titanium, invar, molybdenum, plastic, but of course also “ordinary” stainless steel and steel. Inquire about the possibilities.

Architecture

Architecture

Special processing for

special projects

Special processing for

special projects

Beautiful colours combined with high-quality ground, polished or profiled stainless steel sheets create amazing facades and interior concepts. Inquire about the many options.

Beautiful colours combined with high-quality ground, polished or profiled stainless steel sheets create amazing facades and interior concepts. Inquire about the many options.

Manual processing

Remove welds, apply radii,

remove milling marks.

Or can your product simply only be ground and polished manually?

In that case you can count on the professionals at Van Geenen. Years of experience in this craft ensure the highest achievable quality.

Cleanroom

Cleaning & wrapping

It goes without saying that your product will leave our premises clean and completely wrapped in foil. For this purpose, Van Geenen has Cleaning baths, Ultrasonic baths and clean wrapping rooms at its disposal.

You can even take this a few steps further to clean products on a “high-tech level”. Van Geenen also has a cleanroom and the necessary certificates.

Latest news

News, projects and references

Published on: 16 January 2024

Published on: 2 November 2023